Test

Test 1

| Name | Value |

|---|---|

| Mdf | 9mm |

| Spindle speed | 12000 |

| Feedrate | 62.5 inch/min |

| Passes | 4 |

| Bone | Inside |

| Square | Outside |

| Result : Terrible cut |

Test 2

| Name | Value |

|---|---|

| Mdf | 9mm |

| Spindle speed | 14000 |

| Feedrate | 135 inch/min |

| Passes | 2 |

| Bone | Inside |

| Square | Inside |

| Result : Burn cut |

**The problem why we got burned cut out and burned bit is that the router was spinning against the clock.So we changed the spinning and then we got clear cut

Steps to work with the ShopBot:

Hardware

Before you begin to work with the ShopBot you need to have safetyglasses, safetygloves,eclosed shoes and earpieces.

1.Switch the key on the ShopBot

2.Engang Switch

3.Push the reset button

4.Calibrate the machine

5.Set Home x0 y0

6.Fix your material on the plate

Manually set the bit and the zero Z axis(plate)

Software

The software that comes with the ShopBot is called Aspire.

1.Import yourdesign into aspire

2.Add the toolpaths you want for your design

3.Save your toolpath in .sbp file(Shopbot file) and import it to the ShopBot.

4.Manually turn the spindle on

5.Reposition the XY-Axis and then the Z axis

6.Press start on the software(ShopBot) pop-up box

7.Press start.

8.When finish load another file and repeat the steps.

Invidual assignment

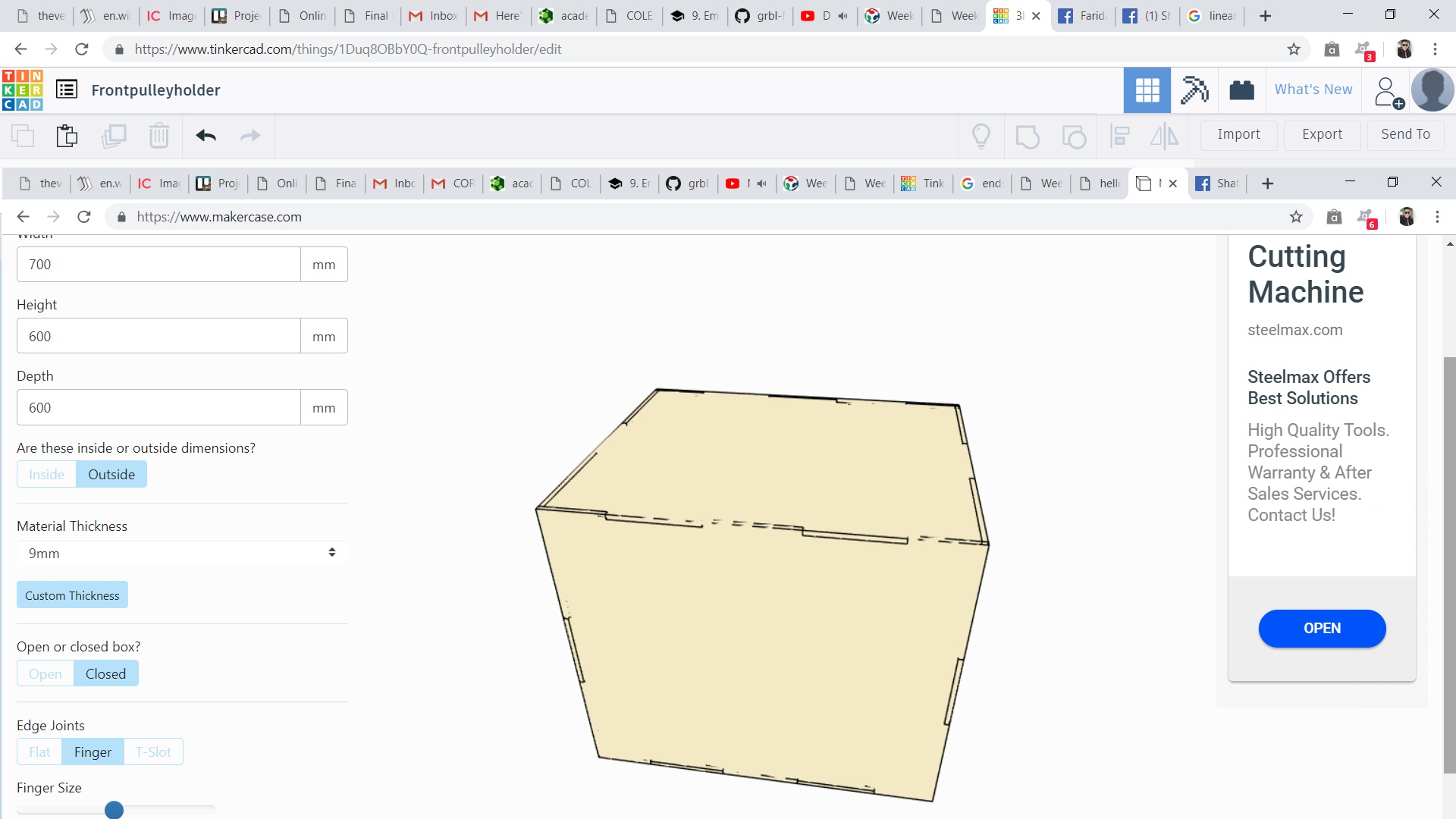

For our invidual assignment make (design+mill+assemble) something big.I decided to make my CNC framework for this week invidual assigment. I used 9mm MDF as material and 5/32mm Endmill to cut the pieces on the ShopBot.

To make the design for my frame i first used makercase to make a pressfit box.The hight is 60cm,depth is 60cm and the width is 70cm.

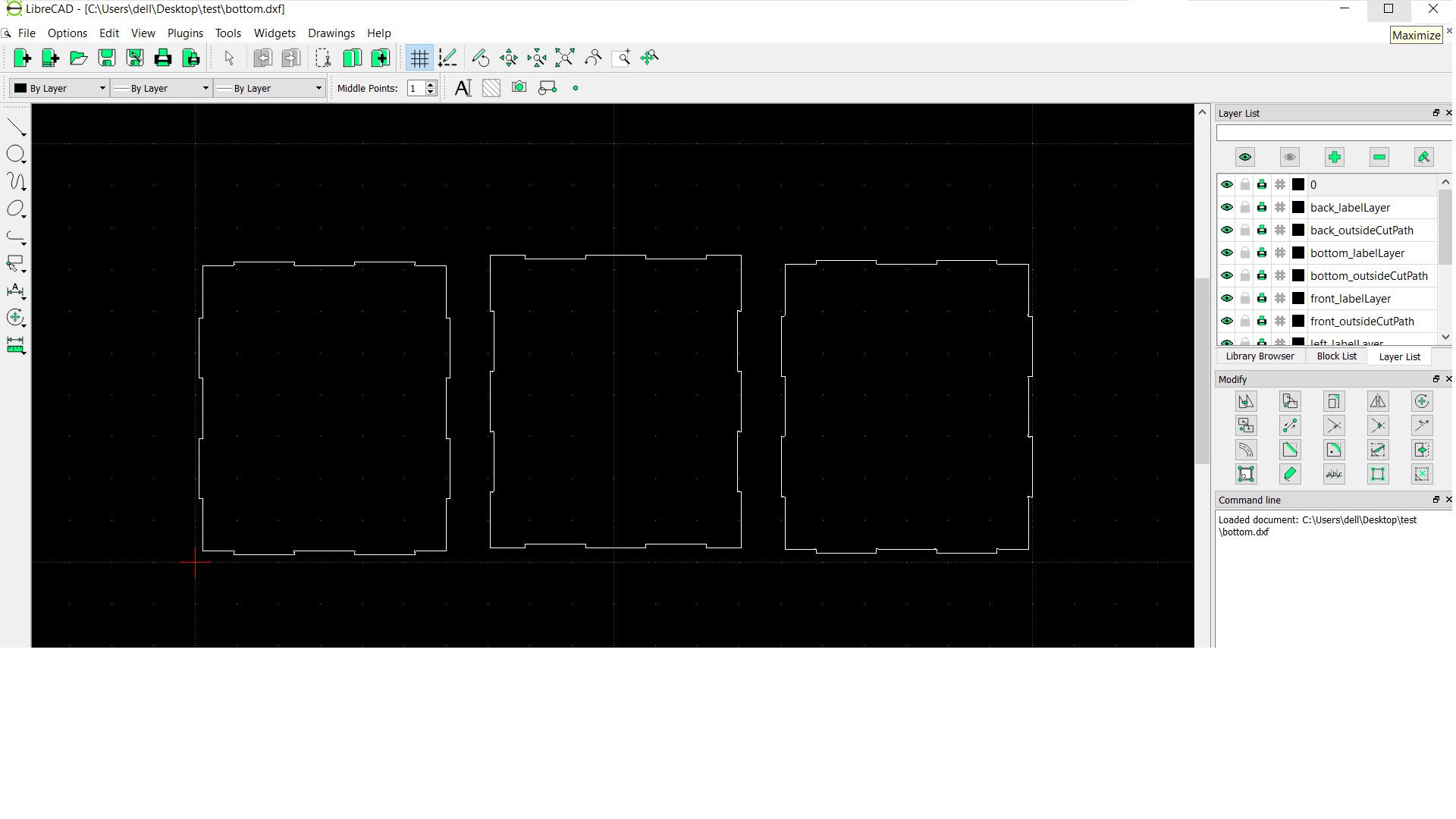

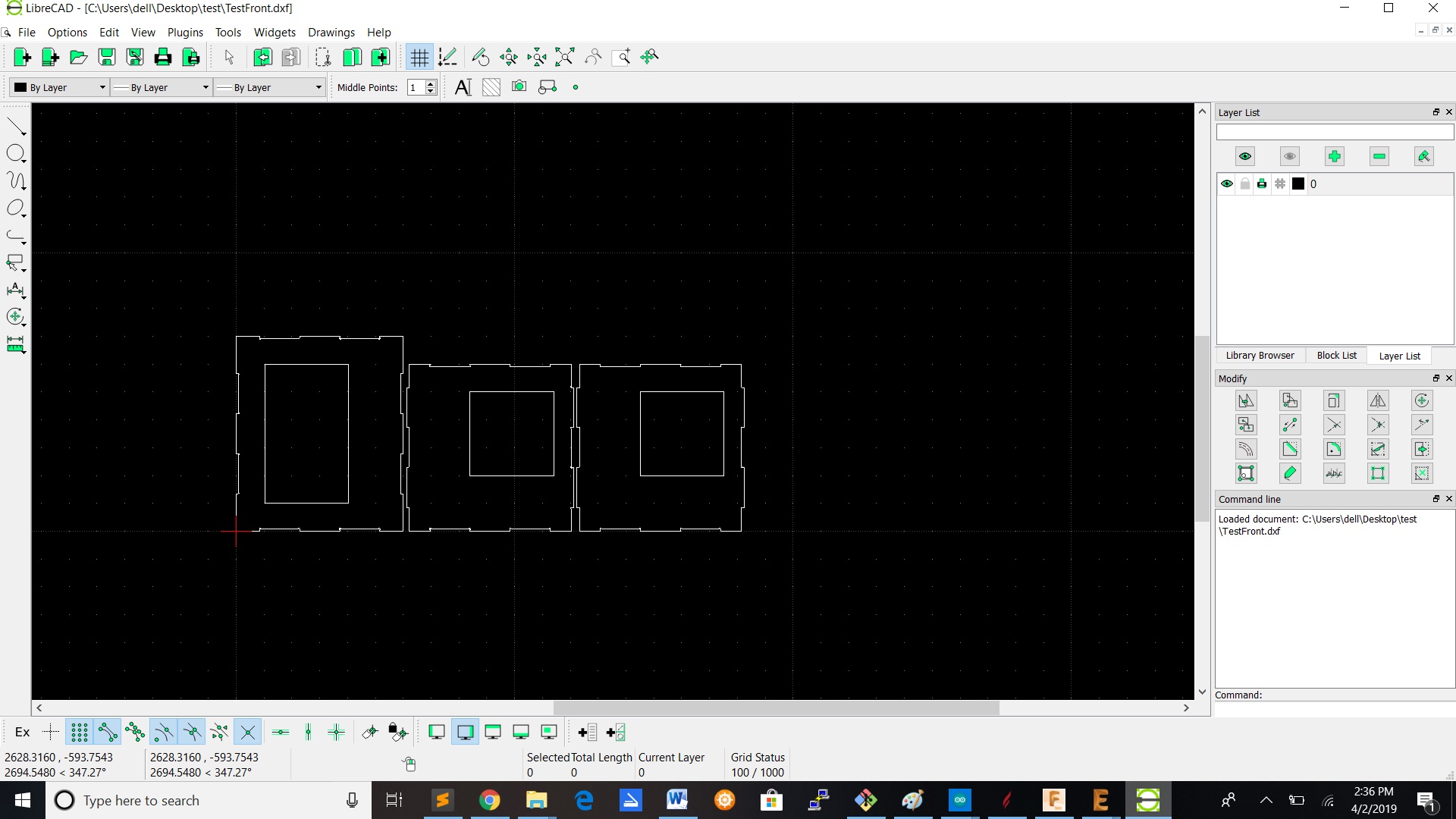

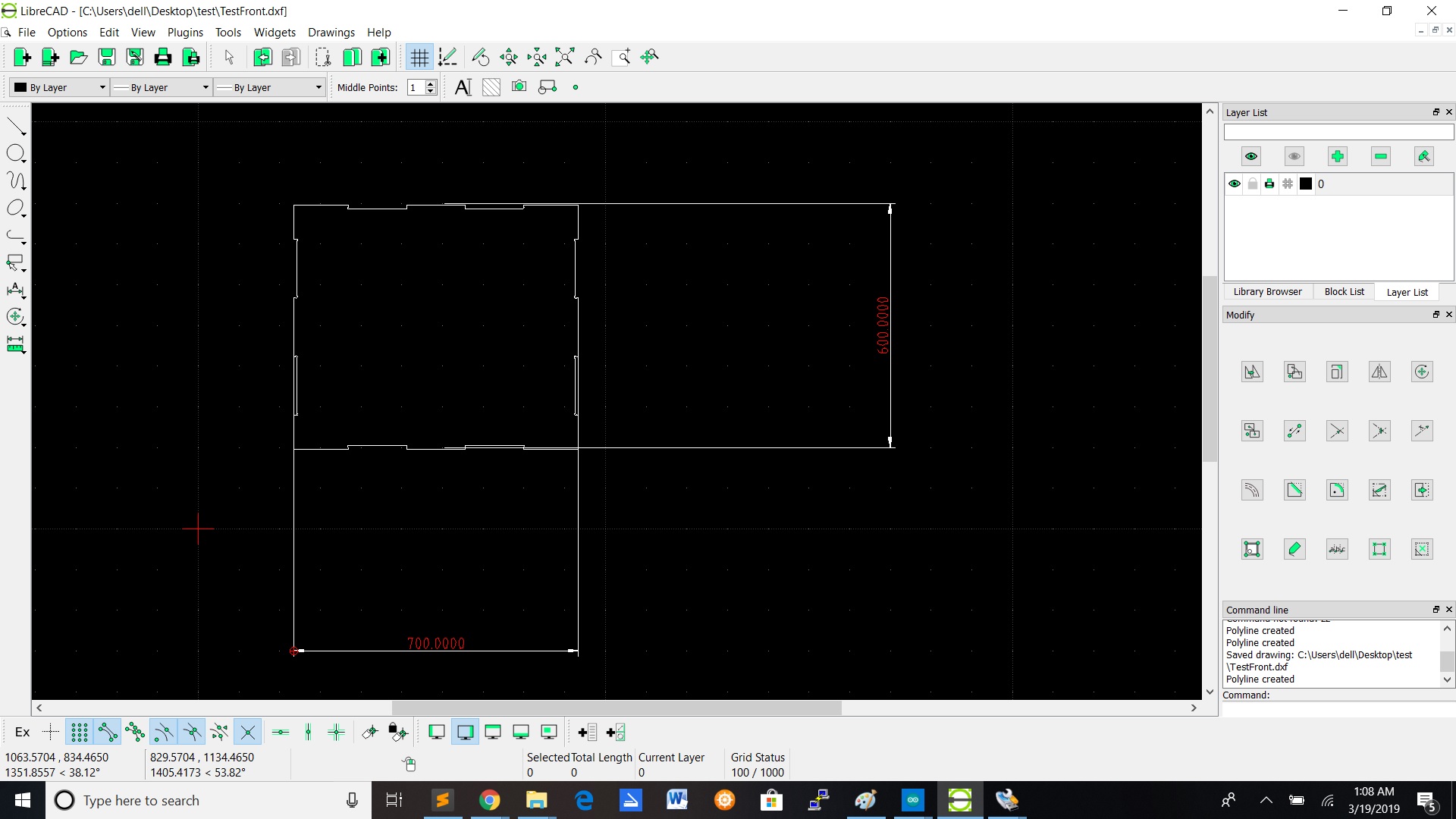

I imported the file in to librecad to edit my design.I made windows at the side and front panel with a margin of 10cm to watch the proces within the CNC machine.

Here you see the windows for watching the process within the CNC machine.

Size of a part of the frame

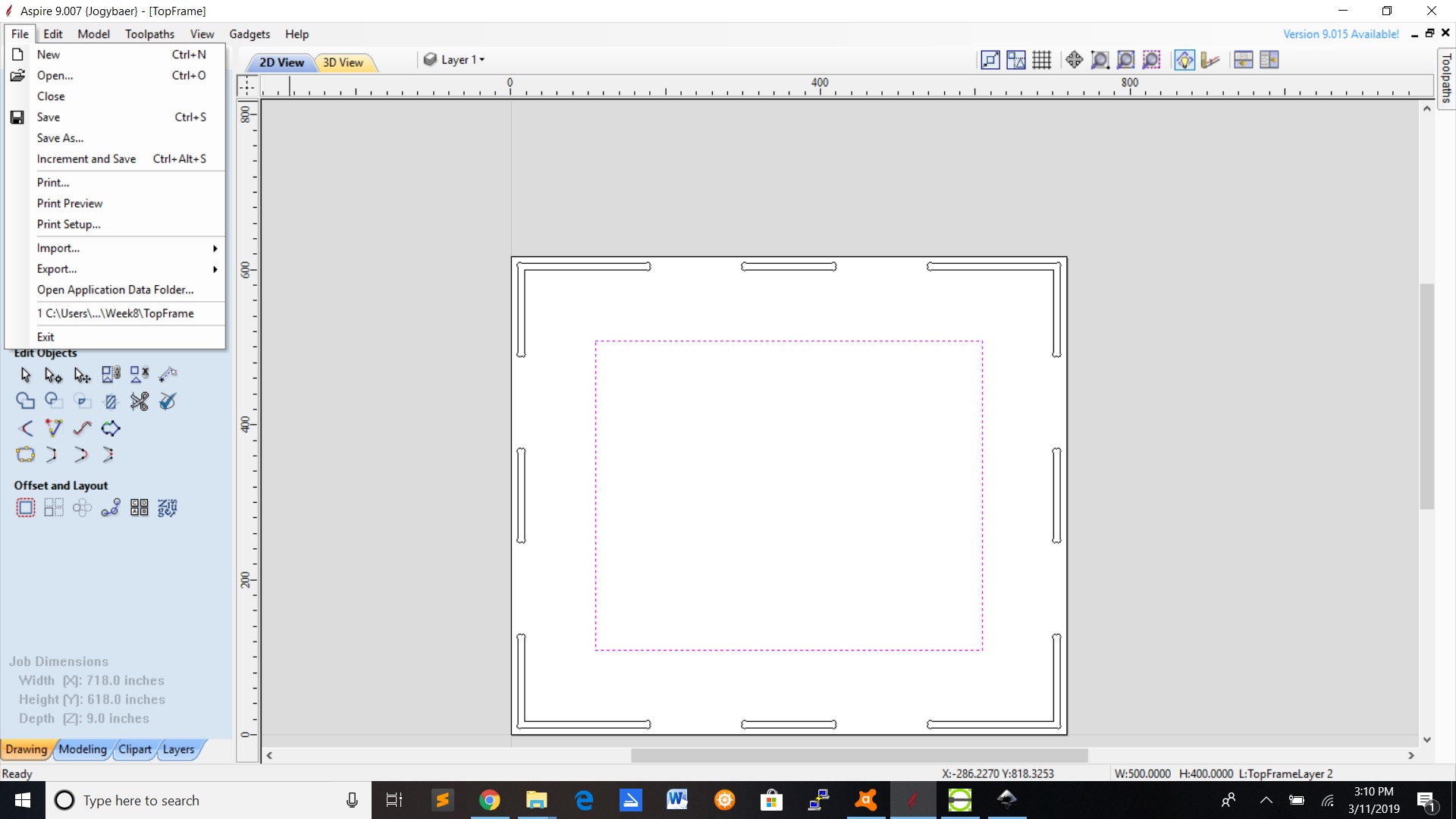

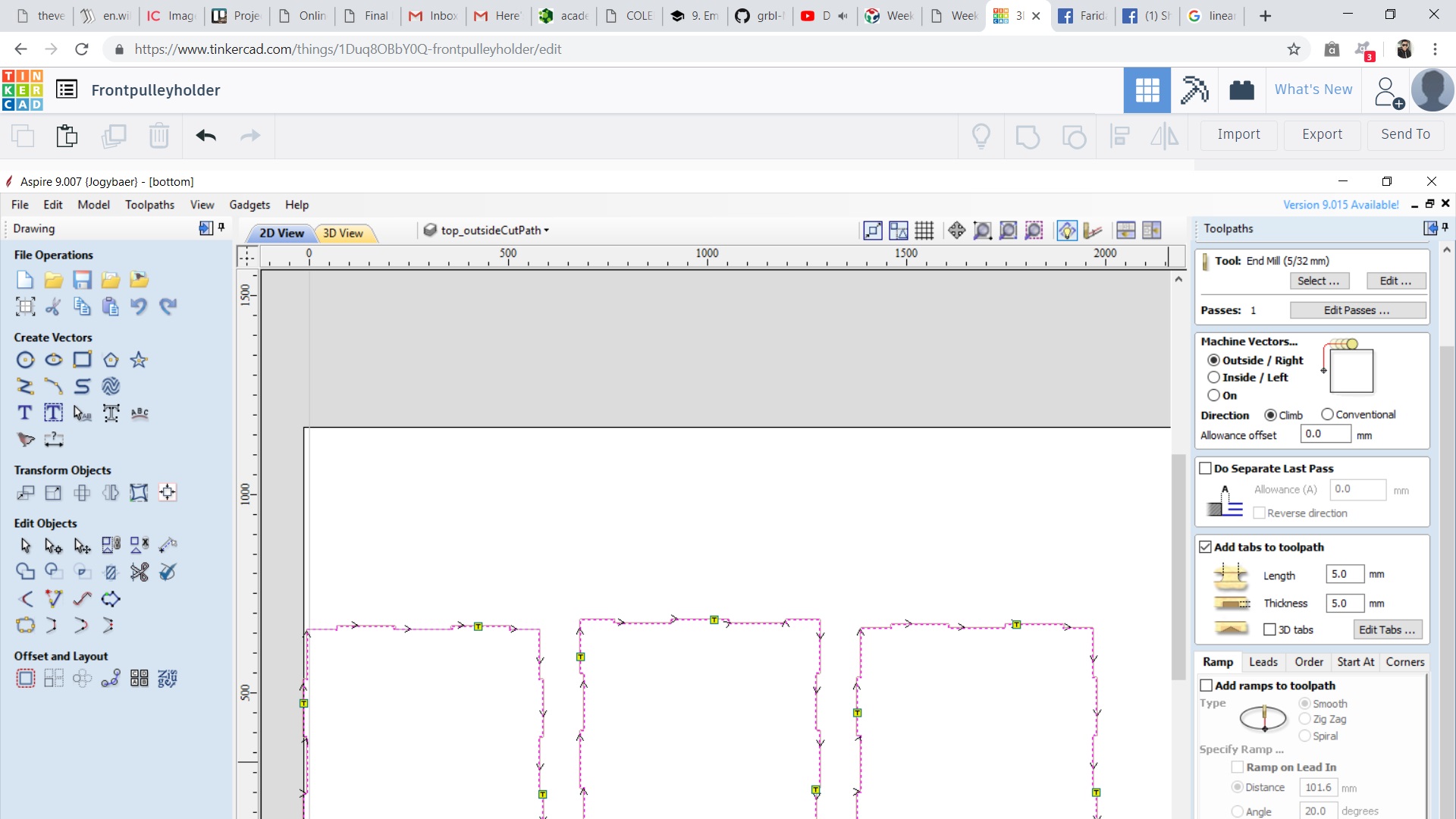

Then you have to save your file as Dxf to open it in Aspire.Open Aspire to import your file to add the toolpath.

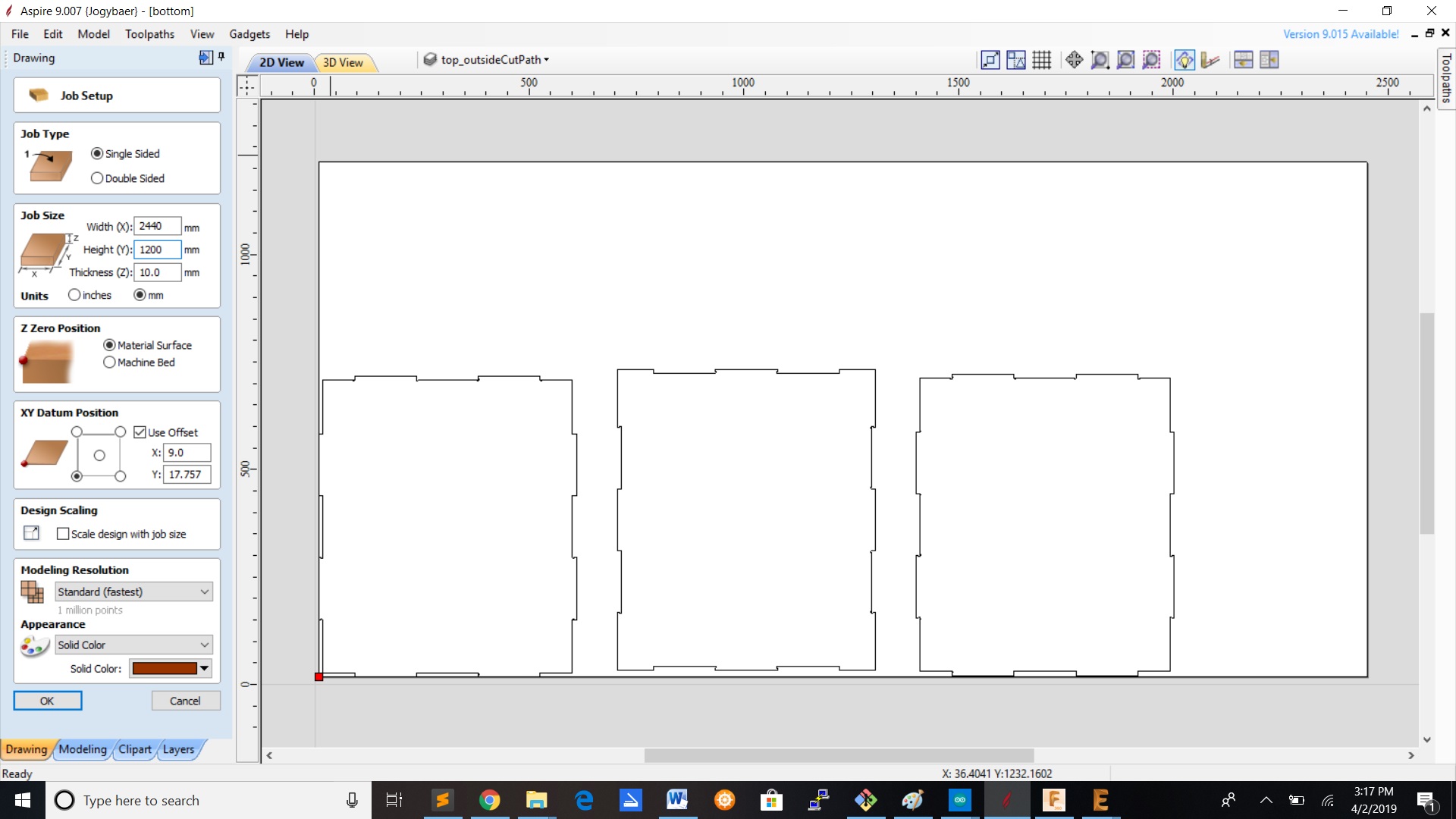

On the left side of your screen you have to add your job setup.The height,the width and the thickness of your material.

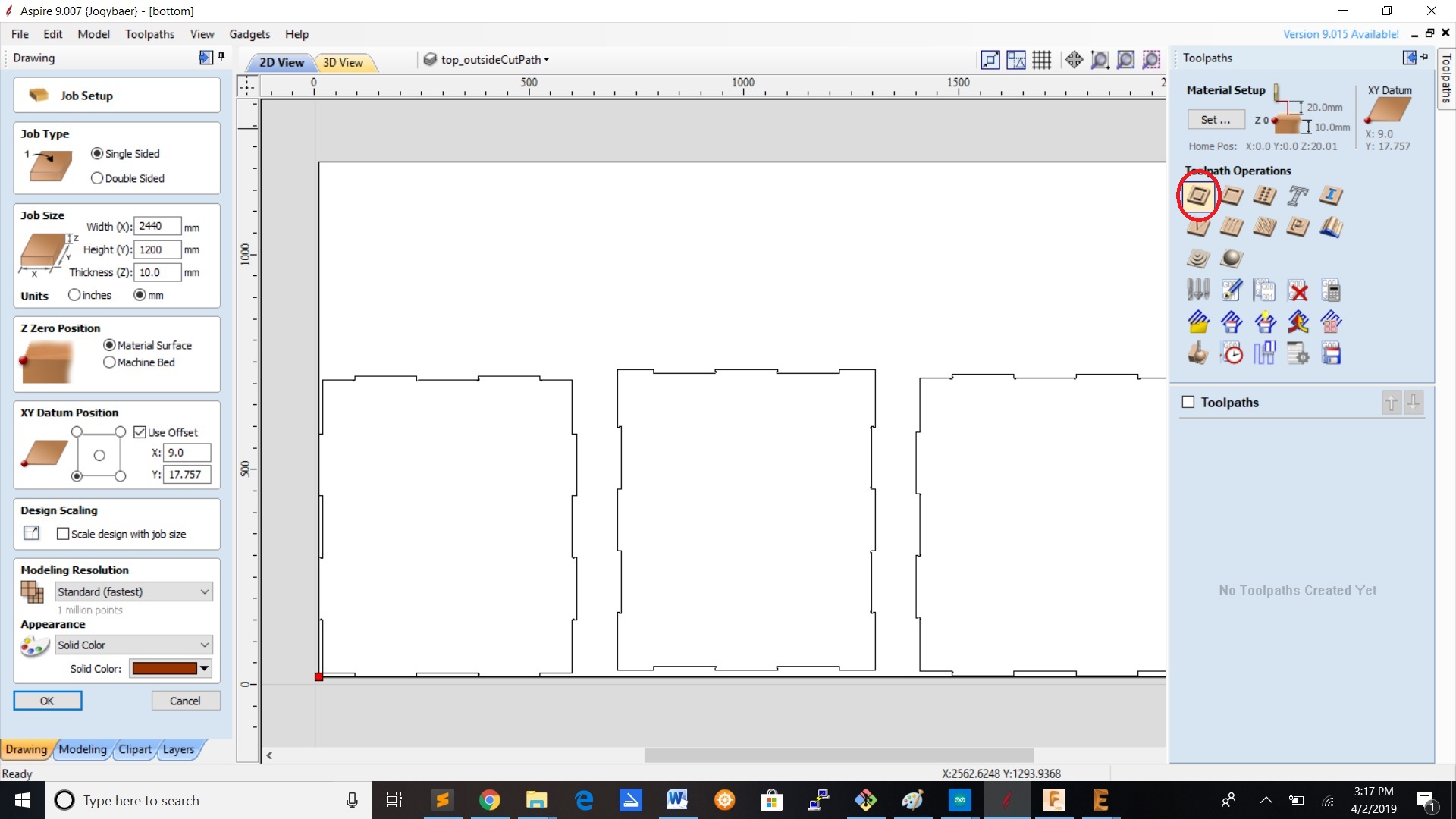

After your done ,on the right side of your screen you have the toolpath option.

Outside cut is when you want that the shopbot has to cut your material on the outside and inside cut is when you have shapes in your design that has to cut in the material.

Also select tabs in the toolpath(a tab is a small flap or strip of material attached to or projecting from something, used to hold, fasten, or manipulate it, or for identification and information).

| Toolpath | Value |

|---|---|

| Start depth | 0mm |

| Cut depth | 10mm |

| Tool | 5/32mm |

| Passes | 3 |

| Machine Vectors | Outside |

| Tabs to toolpath | 5mm 5mm |

| For the tabs you also need to select it on your design |

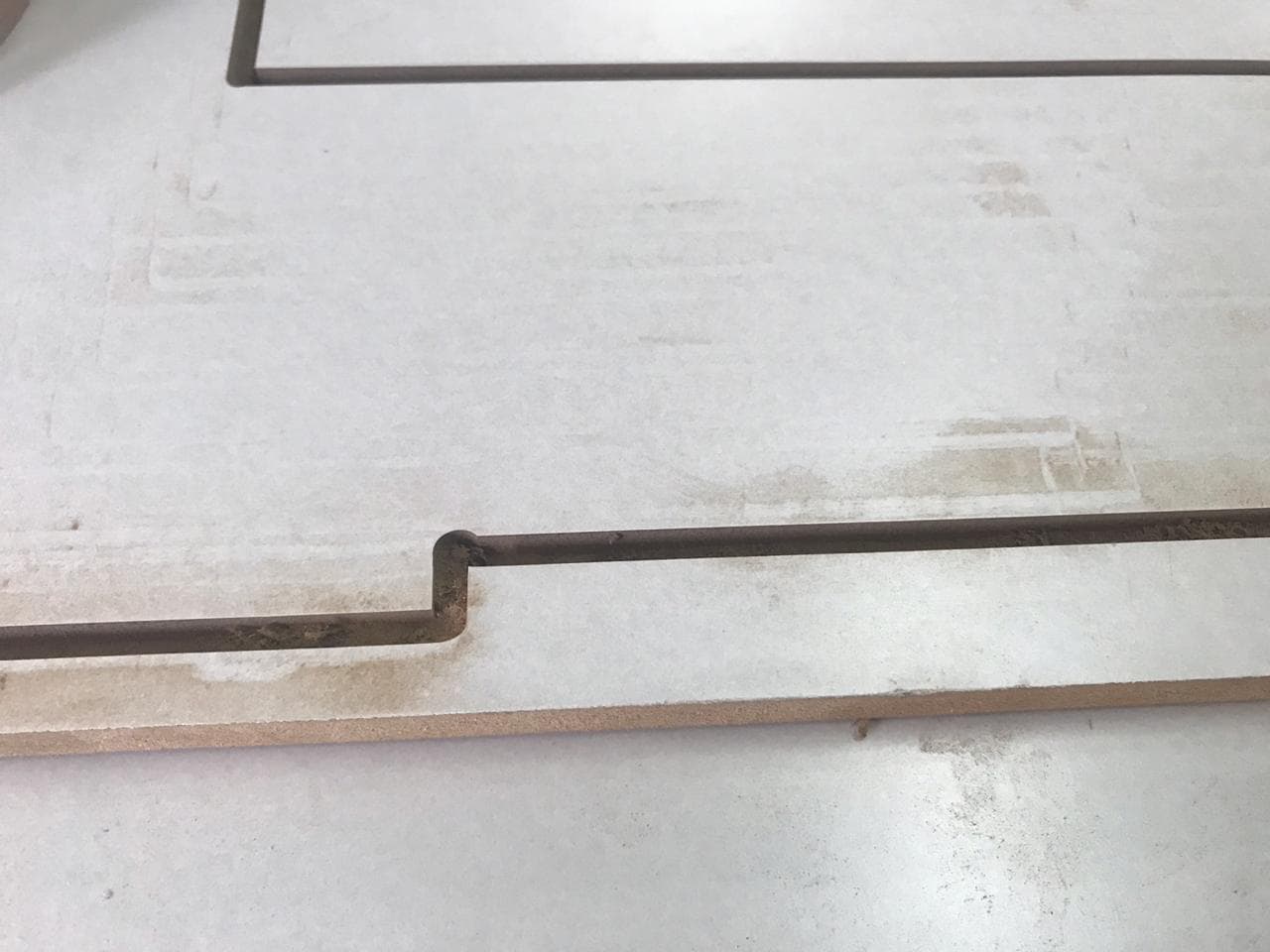

The outcome is :CNC frame

Files

Frame design 1Frame design 2

ShopBot file

The frame